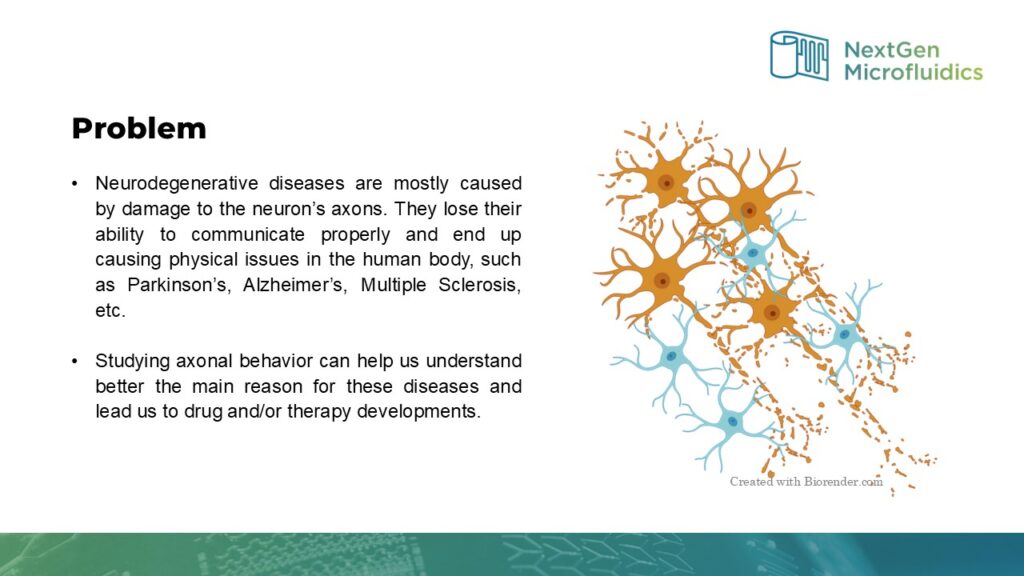

We’re proud to share some results from our Demo Case 4: Large-scale manufacturing of foil-based microfluidic chips for neuron cell culture and axon outgrowth monitoring!

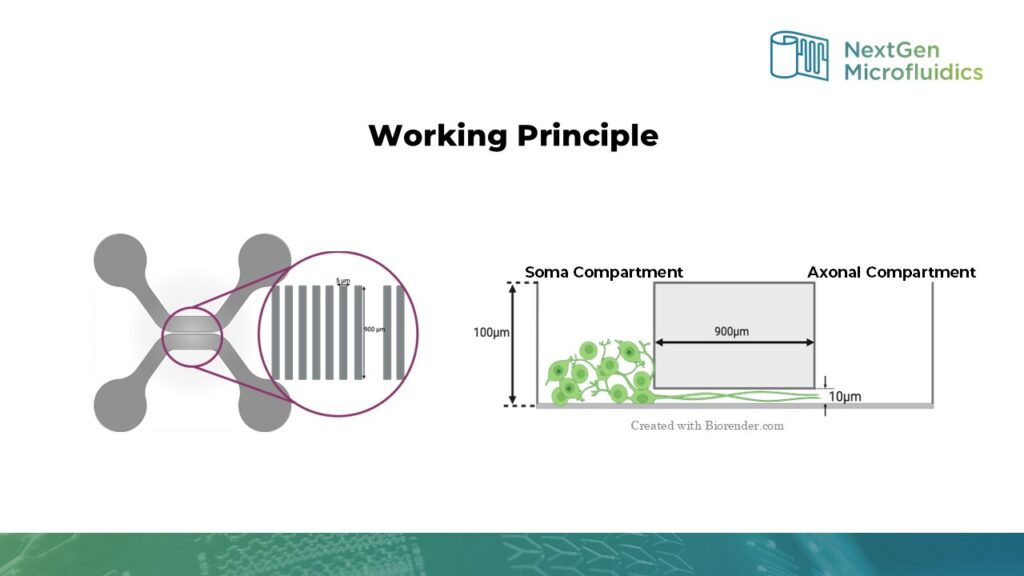

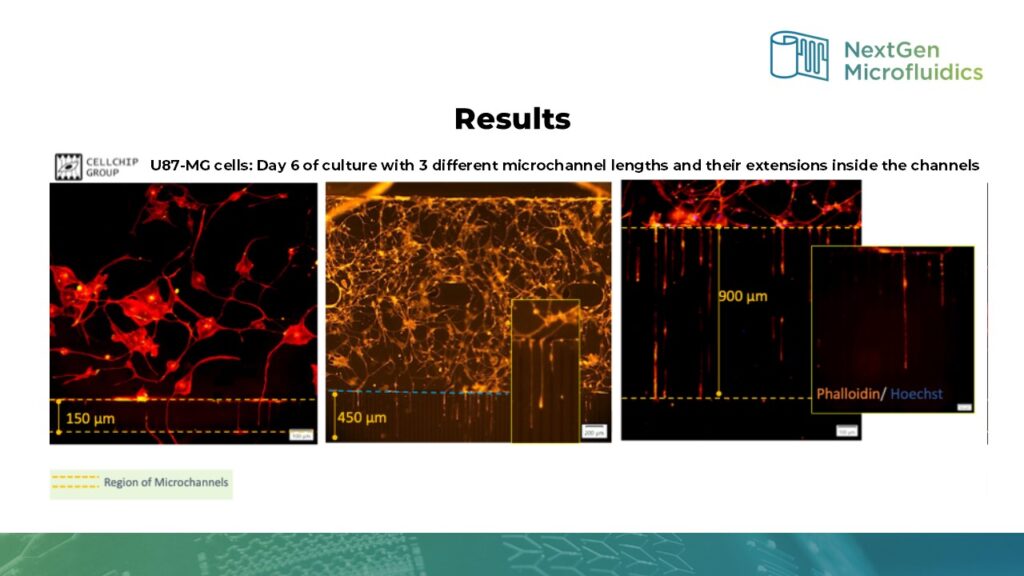

The microfluidic device was designed to separate neuron soma part from their neurites. Therefore, there are microchannels with dimensions of 5x10x900 (WxDxL) connecting those two soma and axonal compartments.

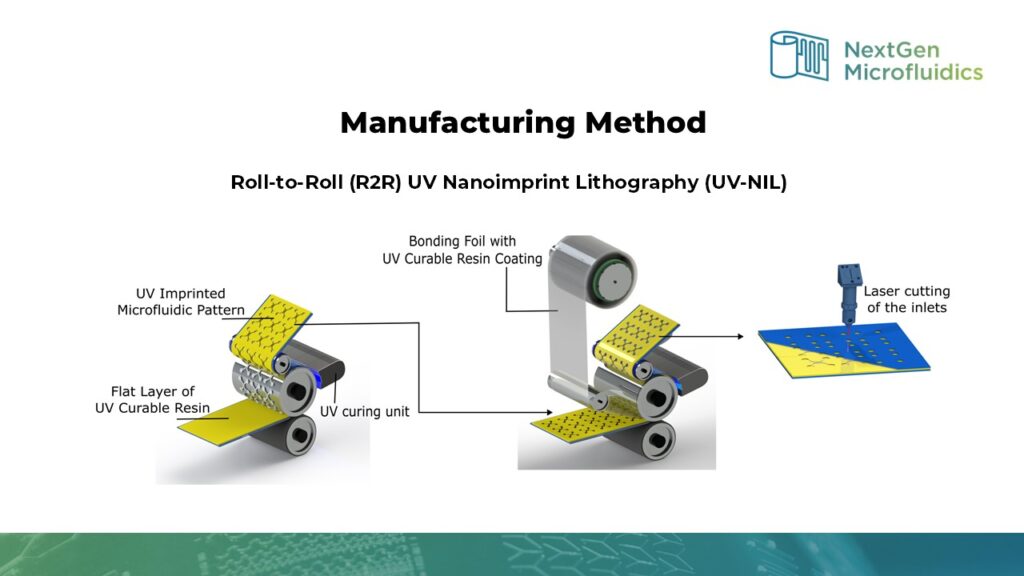

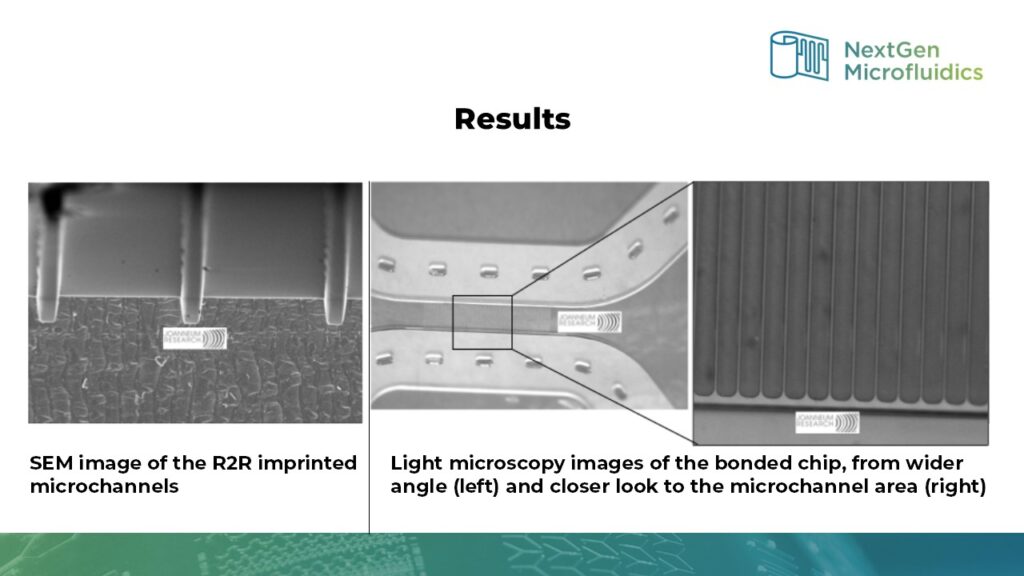

The fabrication method for chips is Roll-to-Roll (R2R), which is a high-throughput and large-scale production line. It uses transparent thermoplastic polymer foils in combination with UV curable liquid resin for hashtagimprinting and hashtagbonding.

Results show that microchannels were fabricated without damages and uniformly. Bonding is also proven with light microscopy images where darker areas are bonded and lighter parts are open (proves that microchannels are not collapsed nor clogged).

In order to validate both design and manufacturing method, U87 glioblastoma cells were seeded on the soma compartment and their axon outgrowth was observed with immunofluorescence staining and fluorescence imaging.

Related Posts

Microfluidics in their PRIME with NGM & Micronit

19. October 2023

by NextGenMicrofluidics

NGM Final Event at Health Tech Hub Styria

10. March 2025

by NextGenMicrofluidics